The case study that included truck loading, traveling, digging and idling was run using a hydraulic excavator, two dumps trucks, a wheel loader and an on-site truck scale. In a long-term performance demonstration at a rock quarry test site in Germany, 19 different fluid formulations were evaluated. Increased productivity and improved fuel efficiency Using more fuel to do the same amount of work is inefficient and expensive, but DYNAVIS technology results in lower oil temperatures and sustained pump efficiency. Stress increases for hydraulic system components such as pumps, hoses, and seals – resulting in reduced service life.

This leads to a downward spiral in performance which causes the equipment operator to "step on the gas pedal" to maintain performance.

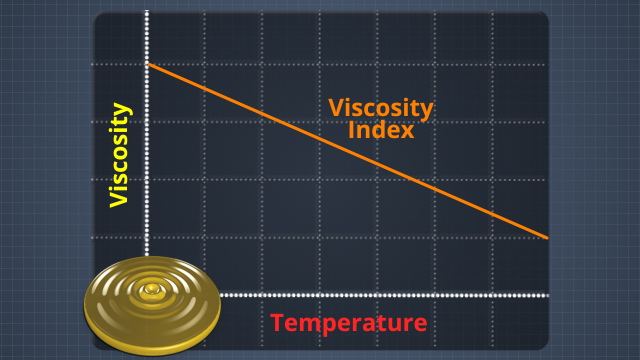

The more fluid that recirculates, the higher the temperatures become within the system because of the additional frictional heat that's created. The fluid recirculates, creating what's known as "internal leakage". High temperatures "thin out" hydraulic fluid's viscosity, leaving the vanes or pistons of the hydraulic pump unable to push an adequate amount of fluid.

WHEN THE ‘HEAT IS ON’, CONVENTIONAL FLUIDS LOSE THEIR ‘PUNCH’ In every climate zone in the world - from temperatures below freezing, to scorching heat - multiple operating shifts, any machine operator, and excavators of all sizes and conditions, DYNAVIS formulated hydraulic fluids guarantee maximum productivity, significant fuel savings, and reliable, sustained performance. Proving the superiority of DYNAVIS has been evident, both in a controlled environment and on-site at real working construction sites. Since 2005, Evonik has tested hundreds of hydraulic fluids, varying viscosity index and shear stability, in a range of mobile construction equipment. Construction machinery is often pushed to its limits.

0 kommentar(er)

0 kommentar(er)